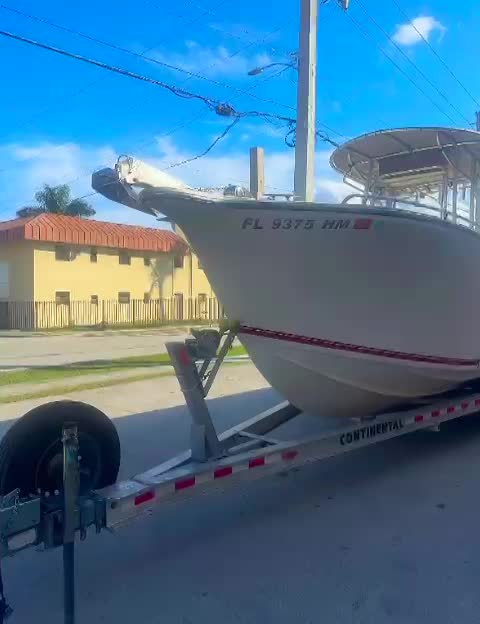

Inboard to Sterndrive Engine Conversion for Boats

1-Remove the inboard engines – Safe disconnection and extraction.

2-Clean and inspect engine mounts and transom areas – Remove any debris or old components.

3-Prepare the transom – Drill or adjust holes as needed for sterndrive installation.

4-Paint the transom – Protective coating to prevent corrosion and improve durability.

5-Reinforce stringers – Strengthen internal support structures for the new sterndrive.

6-Install aluminum angles (angulares) – Ensure secure mounting points for brackets and engines.

7-Bracket installation and adjustment – Align and secure sterndrive brackets for optimal performance.

8-Final inspection and testing – Verify alignment, stability, and proper function before water testing.